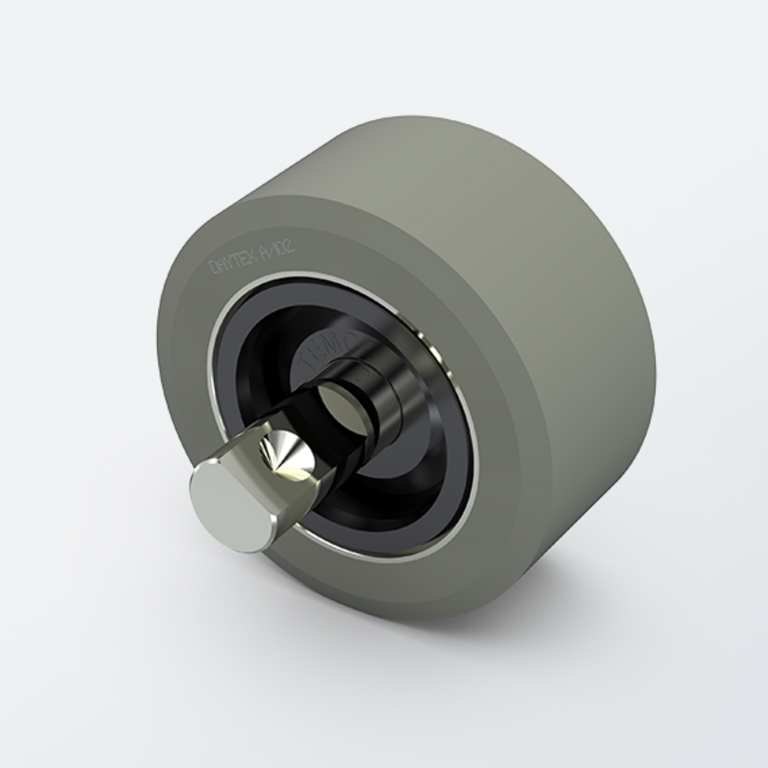

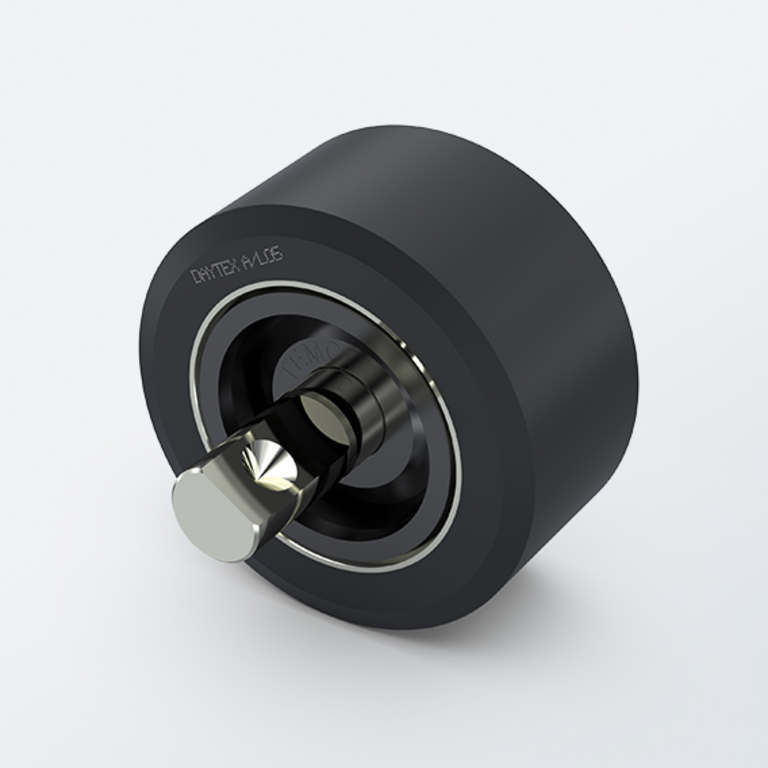

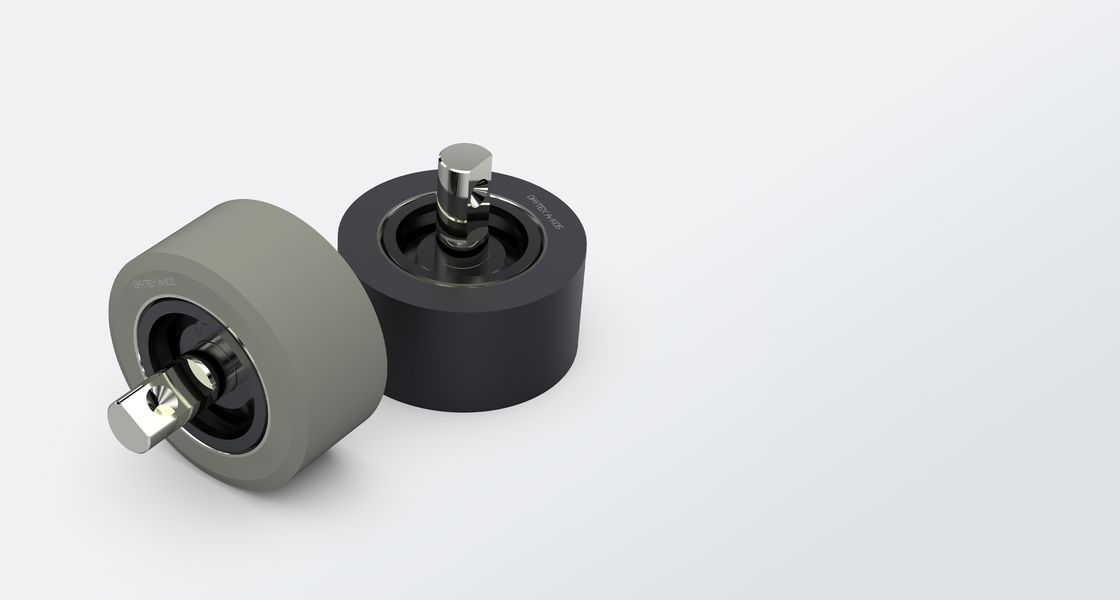

引纱罗拉胶辊LR

成就出色的丝线品质- 通用性广

- 出色的使用寿命

- 最高的质量标准

现代加弹机(DTY)每个锭位最多配备4个皮辊。皮辊会对牵伸过程产生重大影响,进而直接影响变形丝的质量。Temco皮辊很大程度上降低了使用能耗,从而极大地提高了我们客户的竞争能力。

皮辊用于在制造过程中将连续材料(如纺丝或玻璃纤维)压入进料轴。这会产生摩擦锁定效应,保证丝线得到均匀和轻柔的牵伸。

产品特点

- 出色的径向跳动

- 采用集成式滚道,结构紧凑

- 摩擦力矩小,大大降低能耗

- 转速高达2 000米/分钟

- 终身免润滑,无需维护

- 可使用不同的护罩

- 丝线处理柔和

优势

- 优异的耐磨性、抗裂性、耐油性、耐化学性和耐热性

可满足所有普通和高速加弹机对所有纤维和工作条件的最高要求

持久耐用并易于操作,确保更高的生产效率

凭借更高的接触压力,可实现对丝线更出色的夹持力

较低的凹度使漏光降至最低,从而对驱动轴维持恒定的“形状”

在高速生产时能保证更低的振动水平

研磨时变形更小

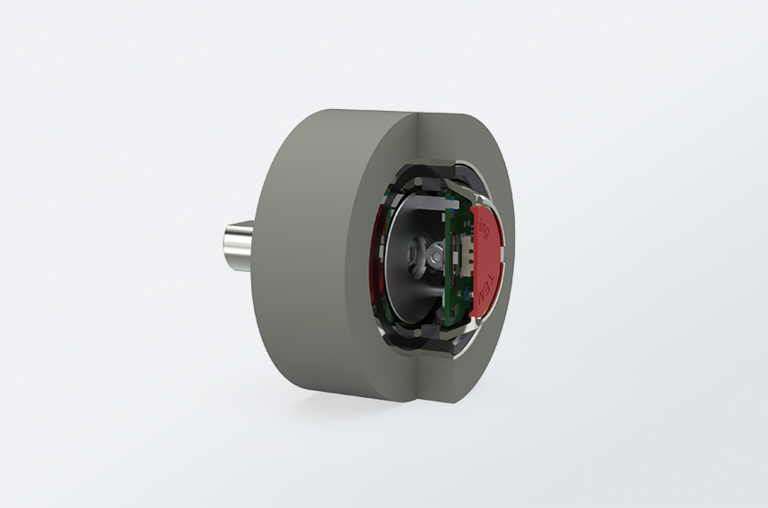

LR & i-Bearing

The monitoring system i-Bearing is now available for the Temco Nip roller LR.

The intelligence of the i-Bearing allows the constant condition monitoring of every single Temco bearing installed within a plant. By measuring speed, vibration acceleration and temperatures, the i-Bearing identifies critical conditions allowing bearings to be replaced before they fail. Machine maintenance is thus optimized and expensive downtime minimized. Customers also get a clear overview, 24/7, of the condition of all installed Temco bearings across their entire plant.

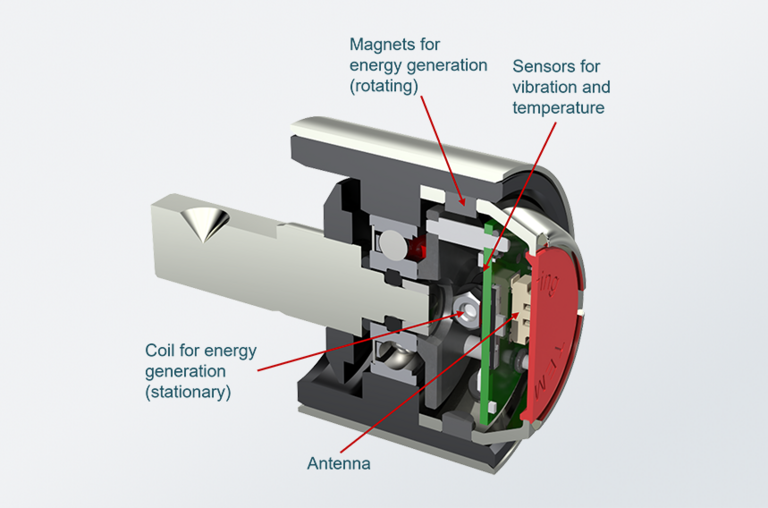

Design and functions LR7035 with i-Bearing

Wireless condition monitoring

Sensors and power supply integrated directly into the bearing

Measurement of speed, bearing vibrations and temperature

No external power supply or battery required as the energy is self-generated

Energy supply via rotating cap with integrated magnets in combination with stationary coil

Measurement directly on the inner ring of the bearing

Adaptable to various TEMCO bearings